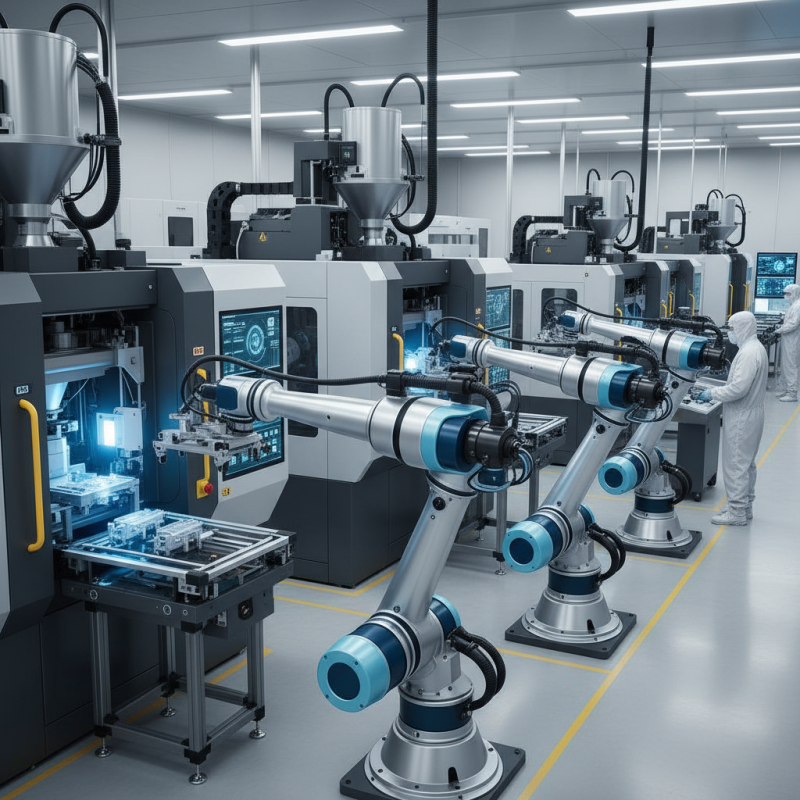

Top Tips for Choosing Injection Machine Robots for Your Factory?

In today's manufacturing landscape, Injection Machine Robots play a crucial role in enhancing productivity and efficiency. According to recent industry studies, the global injection molding machine market is projected to reach $15 billion by 2026, with a significant shift towards automation technologies. As factories strive to improve output, selecting the right injection machine robot becomes essential.

Many manufacturers face challenges in integrating these robots seamlessly. Issues related to compatibility and return on investment often arise. A study revealed that nearly 40% of companies reported difficulties in aligning new technology with existing processes. This highlights the need for careful evaluation before making a purchase decision.

Investing in an injection machine robot should not only focus on initial costs. It is vital to consider maintenance, support, and how the robot will adapt to future demands. In a rapidly evolving sector, ongoing assessment of technology is necessary. The wrong choice may not only strain budgets but also hinder operational growth.

Understanding the Role of Injection Machine Robots in Manufacturing

Injection machine robots play a crucial role in manufacturing processes. They enhance efficiency and precision, which are vital for modern production lines. These robots assist with tasks such as mold positioning, part removal, and material handling. Their ability to operate continuously reduces downtime and boosts output.

Despite their advantages, choosing the right injection machine robots can be challenging. Factories need to consider various factors, such as compatibility with existing machines and workflow. Not all robots are suitable for every production environment. A mismatch can lead to operational inefficiencies and increased costs. Additionally, maintenance requirements might surprise some factory managers. It's essential to plan accordingly.

Automation technology evolves rapidly, and staying updated is difficult. Not every robot offers the same features or flexibility. Some may excel in speed, while others shine in precision. Balancing these factors is key. Regular assessments can help identify if the chosen robots are meeting performance expectations. Investing in the right technology can drastically improve a factory's output, reshaping the future of manufacturing.

Key Factors to Consider When Selecting Injection Machine Robots

When selecting injection machine robots, several key factors must be prioritized. Efficiency is a primary consideration. According to recent industry reports, automation can enhance production rates by up to 30%. However, evaluating the specific needs of your factory is crucial. Not all robots are created equal; some excel in high-speed applications while others offer precision.

Another critical factor is compatibility. Ensure that the robot can integrate seamlessly with your existing machinery. This compatibility can significantly reduce downtime. A survey found that 25% of factories experienced delays due to integration issues. Additionally, consider the scalability of the robot. As production demands fluctuate, being able to adapt is essential.

Training and support should not be overlooked. Many robots require skilled personnel for operation. Investing in training can minimize operational hiccups. Reports indicate that 40% of automation failures stem from inadequate training. Budget constraints can lead to compromises, which may not yield the best long-term results. Balancing cost and quality is often a complex challenge for manufacturers.

Top Tips for Choosing Injection Machine Robots for Your Factory

This chart illustrates the key factors to consider when selecting injection machine robots for your factory, including Load Capacity, Speed, Precision, Cost, and Maintenance Ease.

Evaluating the Technical Specifications of Injection Machine Robots

When evaluating injection machine robots, technical specifications play a crucial role. Start by looking at the payload capacity. It should match your products' weight. If the robot cannot handle the load, it may lead to production delays. Check the robot's reach too. You want it to cover the entire area of your mold. Too short, and it won't reach all points effectively.

Another important specification is speed. The faster the machine operates, the higher the throughput. However, speed shouldn't compromise accuracy. A balance is essential. Look for robots with high repeatability. This minimizes the chances of defects in your products. Note that even minor errors can affect quality.

Additionally, consider the programming ease. A complicated interface can slow down your team. Seek systems that are user-friendly. Flexibility is key as well. Your factory's needs may change, and adaptability is vital. Reflect on your current and future requirements. This thoughtful approach can enhance efficiency and ensure better investment returns.

Assessing Compatibility with Existing Manufacturing Systems

Choosing the right injection machine robot for your factory is crucial. One of the primary considerations is compatibility with existing manufacturing systems. Industry reports show that over 70% of production efficiency relies on seamless integration. If your robot cannot communicate with current machines, it may cause delays.

Before making a decision, evaluate the communication protocols. For instance, can the robot work with your company’s automation software? Checking this aspect is vital. Many fail to consider the importance of compatibility. They rush into purchasing, only to face integration headaches later.

Consider running a pilot test. Collect data on performance relative to existing machines. This approach helps you identify potential bottlenecks early. Investing in proper setup can lead to a better return on investment.

Be wary of overselling promises; not all robots can fulfill the same tasks as existing machinery. A mismatch can lead to reduced productivity. Making informed choices is essential for long-term success in manufacturing.

Budgeting for Purchase and Maintenance of Injection Machine Robots

Investing in injection machine robots requires careful budgeting. The initial purchase cost can be daunting. A basic robot might start at a few thousand dollars, while advanced models can exceed six figures. You need to analyze your production needs. What tasks do you need the robots to perform? More complex tasks typically require more sophisticated equipment.

Maintenance is another essential aspect. Regular upkeep is key to maximizing the lifespan of your robots. Spare parts can be pricey, so set aside funds for replacements. Factor in the cost of skilled technicians. Finding qualified staff may take time. This can delay maintenance schedules and impact production. Training costs for employees also add to the budget.

Consider hidden costs as well. Energy consumption is often overlooked. High-performance robots can lead to increased utility bills. Analyze power usage to avoid surprises. It's wise to create a buffer in your budget for unexpected expenses. These might arise from repairs or upgrades. Inaccurate budgeting could hinder your factory’s growth and efficiency. Reflecting on these factors can prepare you for a smoother transition into automation.