What is a Steering Cylinder and How Does it Work?

The Steering Cylinder plays a crucial role in vehicle dynamics and control. According to a recent industry report by Research and Markets, the global automotive steering system market is projected to reach $45 billion by 2027. Steering cylinders are vital components that aid in precise maneuvering of vehicles. They convert hydraulic pressure into mechanical force, allowing for smooth steering responses.

Many modern vehicles utilize these cylinders for enhanced performance. A well-designed steering cylinder improves the driver's control over the vehicle. However, not all manufacturers achieve this. Some steering cylinders fail to meet safety and performance standards. According to SAE International, subpar steering systems can lead to accidents and loss of control.

The complex nature of steering cylinders requires ongoing innovation. The industry faces challenges related to durability, efficiency, and adaptability. Many designs still rely on outdated technologies. As advancements continue, engineers must focus on creating systems that prioritize safety and responsiveness. The Steering Cylinder remains a focal point in this evolution, driving progress in automotive engineering.

What is a Steering Cylinder?

A steering cylinder is a crucial component in various hydraulic steering systems. It facilitates the movement of a vehicle by converting hydraulic pressure into mechanical force. This mechanism allows for precise steering control, making it easier for drivers to navigate turns and maintain stability.

The steering cylinder consists of a cylinder housing and a piston. As hydraulic fluid enters the cylinder, it pushes the piston to one side. This action moves the steering linkage, turning the wheels. It's interesting how a small amount of fluid can make a big difference in steering response. However, if there are leaks or damage, the system may not function optimally. Drivers might notice a lack of responsiveness, which can be alarming.

Maintenance of the steering cylinder is essential for safe driving. Regular inspections can help identify issues early. However, some owners may neglect this aspect, leading to more serious problems. There’s a certain irony here: ignoring small problems can cause big headaches later. Understanding the role of the steering cylinder can empower drivers to take better care of their vehicles.

Components of a Steering Cylinder

A steering cylinder plays a vital role in the steering system of vehicles and machinery. Its main function is to convert hydraulic pressure into mechanical movement. This mechanism allows for precise steering control. Several essential components work together within the steering cylinder.

The housing is the outer shell that contains the internal parts. It often has a complex design to withstand high pressures. Inside, you’ll find the piston, which moves back and forth. This movement helps direct the vehicle's wheels. Seals are also crucial as they prevent hydraulic fluid leaks. If seals wear out, steering precision can diminish.

Tip: Regularly check your seals for wear. Replacing them promptly can prevent costly repairs down the line.

Moreover, the hydraulic lines facilitate fluid flow to and from the cylinder. These lines must be in good condition. Any cracks or blockages can hinder performance. Additionally, the fluid itself should be at the correct level and viscosity.

Tip: Use the recommended fluid type to ensure optimal function. Low-quality fluids can cause increased wear on components.

A well-maintained steering cylinder ensures the vehicle handles safely. Ignoring signs of problems can lead to larger issues. Listen for unusual noises and watch for inconsistent steering. Keeping the system in good shape requires attention and care.

What is a Steering Cylinder and How Does it Work? - Components of a Steering Cylinder

| Component | Description | Function | Material |

| Piston | A cylindrical component that moves within the cylinder | Converts hydraulic pressure into mechanical movement | Aluminum or Steel |

| Cylinder Body | The outer shell that houses the piston | Holds hydraulic fluid and provides a space for the piston to move | Steel |

| Seal | A rubber or plastic ring that prevents fluid leakage | Maintains hydraulic pressure inside the cylinder | Rubber or Polyurethane |

| Hydraulic Fluid | Liquid used to transfer force in the steering system | Transmits power from the pump to the steering mechanism | Mineral Oil or Synthetic Fluid |

| Mounting Bracket | A structure that holds the cylinder in place | Provides stability to the steering cylinder | Steel |

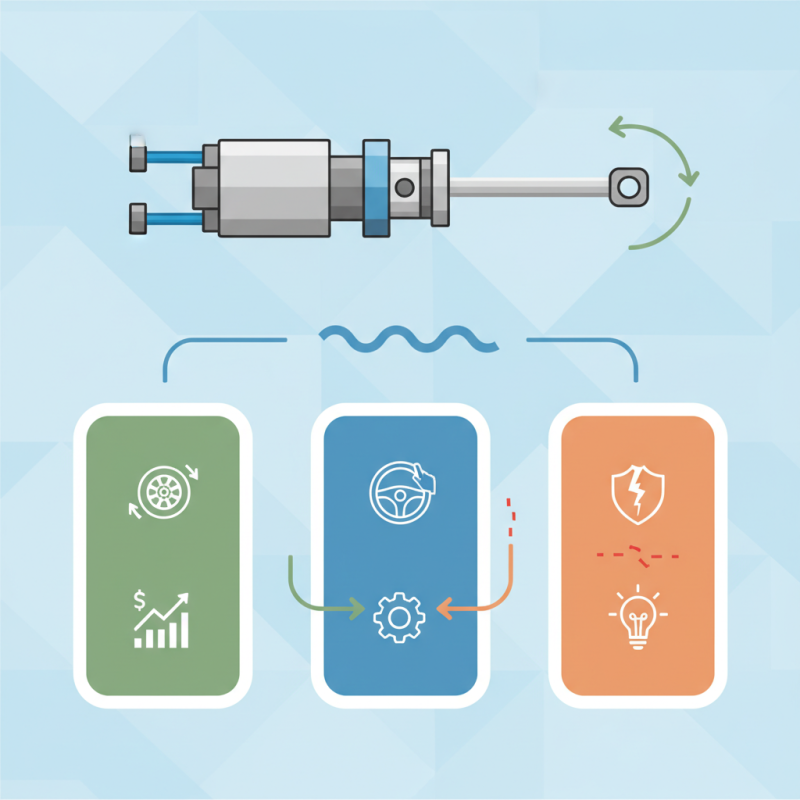

How a Steering Cylinder Functions

A steering cylinder is a crucial component in hydraulic steering systems. It plays a vital role in controlling vehicle direction with precision. This device converts hydraulic pressure into mechanical movement. The hydraulic fluid pressurizes the cylinder, allowing for smooth steering adjustments based on the driver's input. When the driver turns the steering wheel, the system responds instantly. The steering cylinder pushes or pulls the steering linkage, helping navigate twists and turns with ease.

Hydraulic systems have their complexities. An unfortunate leak can render the cylinder ineffective, causing steering difficulties. Proper maintenance is essential to ensure optimal performance. Drivers often overlook this detail. The hydraulic pressure needs to be consistent for reliable function. Small issues can escalate quickly, resulting in safety hazards. It's essential to monitor the system regularly. Some may ignore signs of wear, but these can lead to serious problems. Reflecting on the setup can help in pinpointing potential failures before they occur, ensuring safer driving experiences.

Steering Cylinder Performance Data

This bar chart illustrates the performance metrics of various steering cylinders based on their efficiency and output. Each cylinder has been evaluated on a scale from 1 to 100, reflecting their operational effectiveness and reliability under different conditions.

Common Applications of Steering Cylinders

Steering cylinders are vital components in several applications. They allow vehicles and machinery to change direction smoothly. You will often find them in hydraulic systems. These cylinders convert hydraulic energy into linear motion.

In construction equipment, steering cylinders help operate bulldozers and excavators. They provide the necessary power to steer large machines. The precision offered by these cylinders is crucial for effective operation. In agricultural machinery, such as tractors, steering cylinders enhance maneuverability. Farmers rely on them for efficient fieldwork.

Despite their importance, steering cylinders sometimes face issues. Leaks can occur, leading to reduced performance. Regular maintenance is essential to avoid these problems. Users should be attentive to signs of wear or damage. This preventive approach can save time and money in the long run.

Maintenance and Troubleshooting Tips for Steering Cylinders

Steering cylinders are crucial for vehicle control. Regular maintenance ensures they function effectively. Here are some tips to keep them in top shape.

Check for fluid leaks frequently. Look around the cylinder and hoses. A small leak can lead to bigger problems. If you notice any dampness, act quickly. Replace damaged seals or fittings as needed to maintain pressure.

Examine the cylinder for wear or damage. Rust can weaken the structure. Clean any dirt or grime that collects. A clean surface helps in identifying issues earlier. Listen for unusual noises when turning. They may indicate internal problems.

Remember to routinely inspect the mounting points. Loose fittings can cause misalignment. Tighten any loose bolts. Regular upkeep prevents costly repairs in the long run. Ignoring small issues today can escalate into major failures tomorrow. Stay proactive with your steering cylinder maintenance.