Ultimate Guide to Position Sensors Tips for Accurate Measurements?

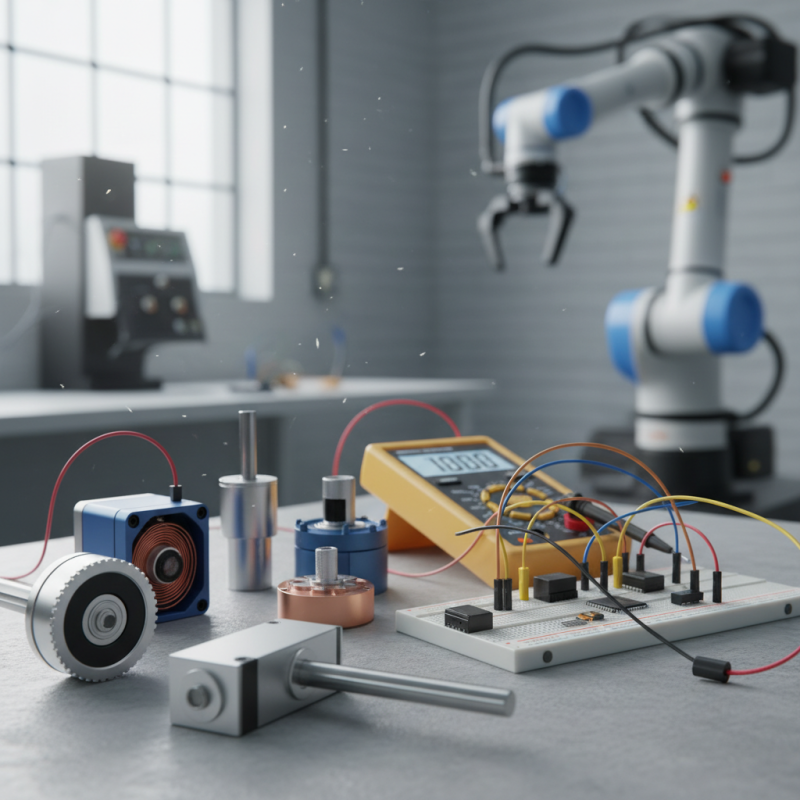

In the world of automation and control systems, the Position Sensor is crucial. These devices measure the position of an object. They provide critical data for various applications. From manufacturing robots to automotive systems, accurate measurements are essential. Position sensors vary in type, like linear and rotary sensors. Each type has unique features and applications.

However, achieving precision with position sensors can be challenging. Factors such as installation, environmental conditions, and calibration affect their accuracy. Some users neglect regular maintenance, leading to errors. Others may misinterpret sensor data, causing failures. It's vital to understand these challenges. Proper awareness can enhance measurement reliability.

This guide explores essential tips for maximizing the accuracy of position sensors. It will delve into setup strategies and maintenance practices. Real-life examples highlight common pitfalls and improvements. Drawing from industry experiences, we aim to refine your sensor implementation. By the end, you’ll better grasp how to leverage position sensors effectively.

Understanding Position Sensors: Types and Technologies

Position sensors are essential in various applications. They help determine the position of an object. Understanding the types of position sensors is crucial for accurate measurements.

There are several types of position sensors: these include potentiometric, inductive, and capacitive sensors.

Potentiometric sensors use resistance changes to gauge position. They are simple and affordable but may lack precision over time.

Inductive sensors, on the other hand, rely on electromagnetic fields. Their accuracy can be excellent, but they may not perform well in harsh environments.

Capacitive sensors detect changes in capacitance. They offer high sensitivity but can be affected by external factors.

Each technology has its pros and cons. Choosing the right one requires careful consideration. Reflecting on your specific needs is vital. A sensor that works well in one situation may fail in another. It's important to test and validate your choices to ensure reliable performance.

Key Principles of Accurate Measurements with Position Sensors

Position sensors are critical for accurate measurements in various applications. They convert position information into electrical signals. Understanding their key principles is essential for optimal performance. For instance, calibration plays a vital role. An improperly calibrated sensor can lead to significant measurement errors. Regular calibration checks help maintain accuracy.

Another important aspect is environmental conditions. Factors like temperature and humidity can affect sensor readings. Ensuring a stable environment is often overlooked. Users must assess these conditions to guarantee precision. Additionally, sensor placement impacts measurement quality. A poorly positioned sensor may not capture the intended data. Evaluating the setup regularly can reveal hidden issues.

In practice, it’s common to encounter challenges. For example, interference from nearby machines can distort signals. Identifying such interference requires ongoing monitoring. The goal is to create a reliable system. Each user’s setup is unique and may require different considerations. Emphasizing these details can lead to better results. Enhancing awareness around these key principles can significantly improve measurement accuracy.

Ultimate Guide to Position Sensors: Accuracy in Measurements

Calibration Techniques for Enhanced Position Sensor Accuracy

Calibration plays a crucial role in ensuring the accuracy of position sensors. According to industry reports, calibration can improve measurement accuracy by up to 30%. This highlights the importance of leveraging effective calibration techniques in various applications. For instance, using a calibrated reference standard during the calibration process ensures that the sensor readings align with known values.

Regular recalibration is often neglected. Many operators overlook this step, leading to potential inaccuracies over time. It's recommended to recalibrate position sensors at least once a year or after significant environmental changes. This practice is vital, especially in industries where precision is paramount, like aerospace or robotics. Subtle drift in readings can occur, and periodic checks and adjustments help maintain accuracy.

Additionally, employing statistical analysis during calibration can enhance the process. Utilizing techniques like least squares fitting allows engineers to identify systemic errors. They can then adjust the sensor's output accordingly. This method can be more effective than standard calibration alone. Ultimately, investing in robust calibration practices can yield significant returns in operational efficiency and reliability.

Common Applications of Position Sensors in Various Industries

Position sensors play a crucial role in various industries. They provide accurate measurements that drive efficiency and safety. In the automotive sector, these sensors are vital for systems like electronic stability control. According to a recent industry report, the automotive position sensor market is expected to grow by 8% annually over the next five years. This growth highlights their importance in ensuring vehicles operate safely.

In manufacturing, position sensors are used in automation and robotics. They help ensure precision in assembly lines. A study indicated that companies using advanced position sensors can increase productivity by 15%. However, challenges remain in integrating these sensors into existing systems. Small inaccuracies in measurements can lead to significant errors in production.

Healthcare also benefits from position sensors in medical devices. Accurate positioning can improve patient outcomes. However, the variability in sensor accuracy raises concerns. Reports suggest that around 20% of these sensors may not meet required standards consistently. Addressing these inconsistencies is essential for the reliability of medical applications.

Troubleshooting and Maintenance Tips for Position Sensors

Position sensors play a crucial role in many industrial applications. Regular maintenance and proper troubleshooting can enhance their performance. Yet, many users overlook these essential practices.

One common issue is signal interference. Metal structures nearby can cause readings to fluctuate. It's important to secure sensors away from such elements. Regular checks for alignment issues can prevent unexpected errors. Realigning sensors can improve accuracy by up to 15%, studies have shown.

Another tip is monitoring environmental conditions. Temperature and humidity can impact readings. If exposure to extreme conditions is unavoidable, consider protective housings. Reports indicate that sensors operating outside their recommended ranges may fail quickly. Inspect connections and wiring regularly as well. Loose wires can lead to erratic sensor behavior.

Documentation is vital. Keep records of maintenance and troubleshooting efforts. This allows for better analysis of recurring issues. Unclear records can lead to repeated mistakes, costing both time and money. A consistent approach to maintenance can lead to a significant reduction in downtime.