How to Choose the Right Metallurgical Bridge Crane for Your Needs?

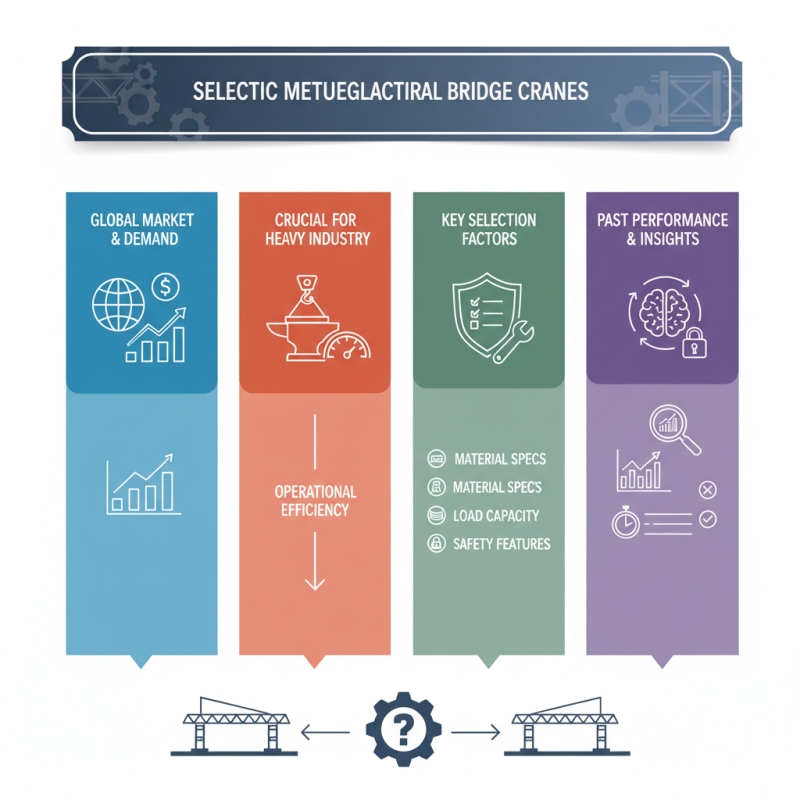

When selecting a Metallurgical Bridge Crane, the decision can be complex. Multiple factors determine what is right for your specific needs. The global market for overhead cranes, including metallurgical types, is projected to reach USD 4.5 billion by 2027, according to industry reports. This indicates a growing demand, highlighting the importance of choosing the right equipment.

Metallurgical Bridge Cranes are crucial for heavy industries, especially in steel production. They efficiently handle molten metal and heavy loads. Research shows that improper crane selection could lead to operational inefficiencies, potentially increasing costs by more than 20%. Hence, understanding your operational requirements and environment is essential.

In the pursuit of efficiency, it's easy to overlook key details. Material specifications, load capacity, and safety features should all align with your operational goals. It's important to reflect on past crane performance data. What worked? What didn’t? Gathering insights will guide you toward making a better decision in selecting a Metallurgical Bridge Crane that suits your needs.

Identifying Your Specific Lifting Requirements for Metallurgical Cranes

Choosing the right metallurgical bridge crane requires a clear understanding of your specific lifting needs. This includes assessing the weight and dimensions of items you'll be lifting. For example, different cranes can handle loads ranging from 10 tons to over 100 tons. The lifting capacity should exceed your heaviest anticipated load to ensure safety.

Consider the height of your work environment. A study revealed that 70% of crane accidents stem from improper clearance. Make sure to factor in the height of the load and any obstacles. If your workspace has low ceilings, a low-headroom crane may be necessary.

Finally, think about the frequency of use. If your operations run daily or continuously, investing in a durable crane is critical. Reports indicate that cranes with higher durability can reduce maintenance costs by up to 30%. Remember, the initial cost is crucial, but long-term reliability matters too. Evaluate all these factors to choose the right crane effectively.

Understanding the Types of Metallurgical Bridge Cranes Available

When choosing a metallurgical bridge crane, understanding the types available is crucial. There are several types, each designed for specific tasks. Common types include single girder, double girder, and cantilever cranes. Single girder cranes are typically lighter and more cost-effective. They are suitable for smaller operations where space is limited.

On the other hand, double girder cranes can handle heavier loads. They offer more stability and are well-suited for larger facilities. Some variations include those with specific hooks for different materials. Each type has its unique features and benefits, which means one may not fit all needs.

Consideration of the load capacity is essential too. Higher capacities increase cost and complexity. However, underestimating your needs can lead to issues down the line. It's important to reflect on your operational requirements. Balancing budget and functionality can be challenging, but it's necessary for optimal performance.

How to Choose the Right Metallurgical Bridge Crane for Your Needs?

| Type of Metallurgical Bridge Crane | Load Capacity (tons) | Span Length (meters) | Lift Height (meters) | Power Source |

| Single Girder Bridge Crane | 5 | 10 | 6 | Electric |

| Double Girder Bridge Crane | 10 | 15 | 8 | Electric |

| Explosion-Proof Bridge Crane | 15 | 20 | 10 | Electric |

| Heavy-Duty Bridge Crane | 20 | 25 | 12 | Diesel |

| Customizable Bridge Crane | Variable | Custom Length | Variable | Electric/Diesel |

Evaluating Load Capacity and Safety Features

When selecting a metallurgical bridge crane, evaluating load capacity is crucial. Load capacity determines the maximum weight the crane can handle safely. According to industry data, over 70% of crane accidents occur due to exceeding load limits. It’s vital to choose a crane that not only meets but exceeds your operational requirements. Many experts recommend leaving a margin of 20% above your maximum load capacity. This safety buffer can prevent potential mishaps.

Safety features are equally important. A crane should include automatic overload protection. This feature stops operation when loads exceed safe limits. Additionally, look for cranes with emergency stop buttons. They offer quick response capabilities in emergencies. Studies reveal that cranes with advanced safety measures reduce accident rates significantly, often by more than 15%. However, safety training for operators is often overlooked. Without proper training, even the best safety features can fail.

Regular maintenance is another area needing attention. Inspections should happen frequently to ensure all safety mechanisms function correctly. Industry reports suggest that poorly maintained cranes are three times more likely to be involved in accidents. Thus, while selecting the right crane, consider both load capacity and safety features together with ongoing maintenance practices.

Considering Operational Environment and Space Constraints

When selecting a metallurgical bridge crane, the operational environment plays a crucial role. Complex environments, such as steel mills or foundries, often have unique challenges. High temperatures and exposure to dust can affect crane performance. For instance, a report by the International Institute of Crane Engineers noted that environments above 40°C dramatically reduce the lifespan of certain cranes. This means, before deciding, conducting a thorough analysis of temperature variations and potential contaminants is vital.

Space constraints can also dictate crane selection. Limited headroom or floor space can limit options. For example, a taller crane might disrupt workflow in a low-ceiling area. According to industry data, optimizing vertical space can increase crane efficiency by over 30%. This calls for precise measurements and layout planning. It can be tempting to choose a larger crane for future needs, but if space is already tight, that choice could be limiting. Buyers should think carefully about their immediate environment to prevent future operational frustrations.

The balance between operational requirements and space restrictions is delicate. Many companies find themselves needing to adapt their crane after installation. Refitting a crane incurs significant costs. Therefore, it is wise to engage with professionals who understand the nuances of space and environmental challenges. These insights can inform decisions and potentially save time and resources in the long run.

Budgeting and Maintenance Considerations for Crane Selection

Choosing the right metallurgical bridge crane involves considering your budget and maintenance needs. Budgeting is critical. It impacts the overall cost of ownership. Look beyond the initial price. Think about the installation and operational costs. There may be hidden expenses in maintenance and repair.

Tips: Create a detailed budget. Include all potential costs. Consider lifespan and efficiency. Sometimes, a cheaper model may incur higher long-term costs.

Maintenance is also key in crane selection. Poor maintenance can lead to costly downtime. Inspect frequently and establish a comprehensive maintenance plan. This will enhance safety and productivity. Remember, certain cranes require more upkeep.

Tips: Research maintenance schedules for different models. Examine each crane’s design for ease of repair. Simplicity can save you time and money. Choose a crane that aligns well with your operational workflow.