2026 Best Plastic Injection Mold Designs and Techniques?

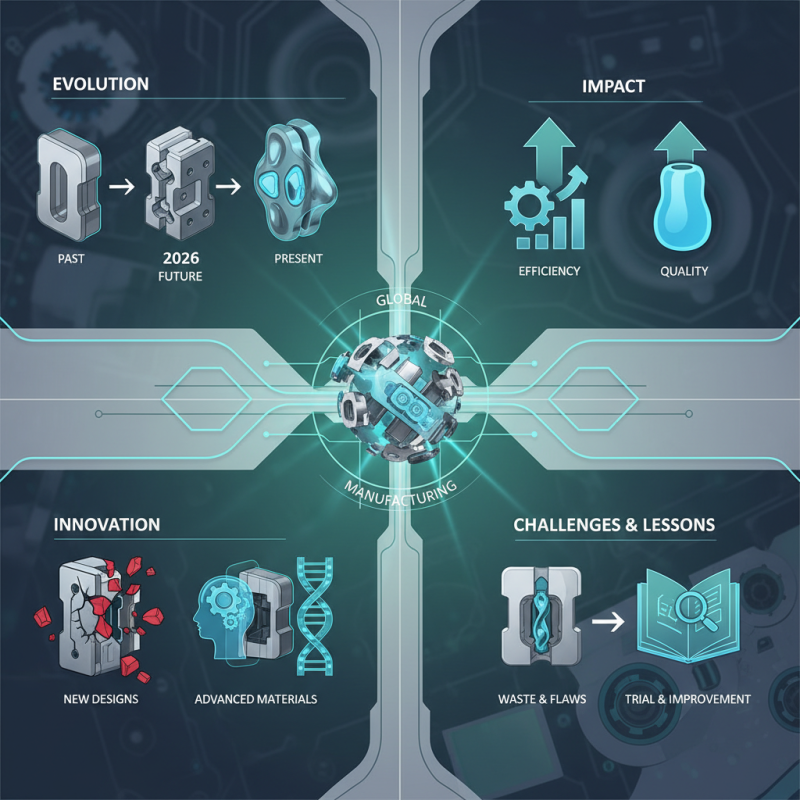

The world of plastic manufacturing continues to evolve. Plastic Injection Mold designs play a crucial role in this transformation. These molds are essential for producing various plastic parts, from simple bottles to complex automotive components.

In 2026, innovation is at the forefront. New techniques are emerging, pushing the boundaries of what we can create. Understanding the best designs allows companies to enhance efficiency and product quality. However, achieving perfection in these molds is not always straightforward. Challenges like material waste and production flaws remain.

Reflecting on past designs can offer valuable lessons. Each mold carries a story, often marked by trial and improvement. Embracing both the successes and failures is vital for future advancements. The journey of mastering the art of Plastic Injection Mold design reflects the industry's complex nature. It is not just about making things; it is about making them better.

Innovative Trends in Plastic Injection Mold Designs for 2026

As we approach 2026, the realm of plastic injection mold design is undergoing a significant transformation. Innovative trends are emerging, shaped by a growing emphasis on sustainability and efficiency. Designers are increasingly utilizing biodegradable materials. This shift reflects a deeper commitment to environmental responsibility. Moreover, advanced simulations are being employed more frequently. These allow for precise calculations, improving mold accuracy and reducing waste.

In addition, the integration of automation is reshaping the mold-making process. Robots streamline production, enhancing speed and precision. However, this shift also raises questions. Are we relying too much on technology? There's a delicate balance to maintain between human touch and automation. Designers must continually refine their techniques. Embracing these new technologies can be daunting, as they require substantial investment and training.

Furthermore, aesthetic aspects of molds are also evolving. Custom textures and complex geometries are gaining popularity. Yet, not all designs hit the mark. Some may become overly complicated or impractical. It is crucial for designers to reflect on functionality over form. Achieving the right balance will determine the effectiveness of these innovative techniques in the years to come.

Key Techniques for Enhancing Plastic Injection Mold Efficiency

Plastic injection molding is a crucial manufacturing process. Enhancing mold efficiency can lead to significant cost savings. Key techniques can optimize production cycles and improve product quality.

One effective method is regular maintenance of molds. Over time, wear and tear occur, causing defects in the final product. Inspecting molds frequently can prevent these issues. Some engineers overlook small damages. These can drastically affect efficiency in the long run.

Another technique involves optimizing cooling channels. Properly designed channels can reduce cycle times. Cooling too slowly leads to longer production times. Consider using simulation software to visualize flow paths. Many teams miss this important step, limiting their understanding of mold performance.

Tips for enhancing mold efficiency are vital. Always keep a close eye on temperature control. Poor thermal management can lead to uneven shrinkage. Moreover, ensure materials are stored properly to avoid contamination. This attention to detail can prevent failures. Lastly, training staff on these techniques helps maintain consistent quality.

2026 Best Plastic Injection Mold Designs and Techniques

| Design Technique | Description | Efficiency Improvement | Common Applications |

| Hot Runner Systems | Utilizes heated channels to minimize material waste. | Reduces cycle time and material costs. | High-volume production of small parts. |

| Multi-Cavity Molds | Incorporates multiple cavities in a single mold. | Increases production efficiency by reducing cycle time. | Producing numerous identical parts simultaneously. |

| Foam Injection Molding | Inserts gas into the material for lightweight structures. | Reduces material usage while improving insulation. | Packaging and automotive components. |

| Family Molds | Combines different part designs into one mold. | Maximizes material flow efficiency. | Consumer products with multiple components. |

| 3D Printed Molds | Rapid prototyping of molds using 3D printing technology. | Speeds up design iteration and reduces lead time. | Small batches and prototype development. |

Materials Selection for Optimal Plastic Injection Mold Performance

The selection of materials for plastic injection molds is critical. It affects durability and overall performance. According to industry reports, about 70% of mold failures are due to the improper choice of materials. This emphasizes the need for careful consideration in material selection.

When creating molds, steel and aluminum are commonly used. Steel is known for its strength and resistance to wear. However, it is also heavy and more expensive. On the other hand, aluminum molds are lighter and can be made quicker. Yet, they may wear out faster under certain conditions. This trade-off can significantly affect production efficiency.

Additionally, advanced polymers are gaining traction. They offer unique properties that can enhance mold performance. For instance, carbon fiber-reinforced plastics show superior strength-to-weight ratios. But these materials come at a higher cost. The balance between cost and performance must always be evaluated. Operators should not overlook the environmental impact as well. Sustainable materials are increasingly important in the industry. Inadequate attention to these factors may lead to inefficiencies and increased waste.

Sustainability Practices in Modern Plastic Injection Mold Manufacturing

Sustainability in plastic injection mold manufacturing is increasingly critical. The industry faces pressure to minimize its environmental impact. Many companies now explore eco-friendly materials. Biodegradable plastics are becoming more common. These materials can reduce the long-term waste associated with traditional plastics.

Energy consumption is another major issue. Minimizing energy use during the injection process is important but often overlooked. Manufacturers are adopting energy-efficient machinery. Still, this transition is slow and can be costly. Regular assessments of energy consumption practices are essential. Companies need to reflect on their impact and seek better solutions.

Recycling is an important element of sustainable practices. However, not all plastics can be easily recycled. Developments in recycling technologies are needed, yet challenges remain. Many facilities struggle to implement effective recycling programs. A focus on creating circular economies can drive change. Manufacturers must prioritize sustainability, but the journey is not simple. It requires commitment and constant reevaluation of existing processes.

2026 Best Plastic Injection Mold Designs and Techniques

This chart illustrates the trends in sustainable practices in modern plastic injection mold manufacturing, highlighting the adoption of various techniques in 2026.

Future Challenges and Solutions in Plastic Injection Mold Technology

The future of plastic injection mold technology faces numerous challenges. As industries demand more sustainable options, manufacturers must adapt. According to a report by Research and Markets, the global demand for sustainable plastics is expected to grow at a CAGR of 4.5% through 2027. This shift urges the need for innovative mold designs that reduce waste and energy consumption.

Another significant challenge is the integration of Industry 4.0 principles. Smart manufacturing techniques are gaining traction. They promise efficiency but require a skilled workforce to implement them. Many companies struggle with this transition. A survey by Deloitte revealed that 56% of manufacturers are uncertain about adopting smart technologies. Investing in training and development is vital for future success.

Furthermore, the increasing complexity of products raises mold design intricacies. Designers face issues like heat distribution and cycle times. These factors can affect production efficiency. However, advancements in simulation software may offer solutions. Still, the learning curve remains steep for many companies. Embracing new technologies might be necessary but is not without risks. The balance between innovation and practicality will be a defining factor in molding technology's future.