2026 Best Motorized Valve Options for Efficient Control?

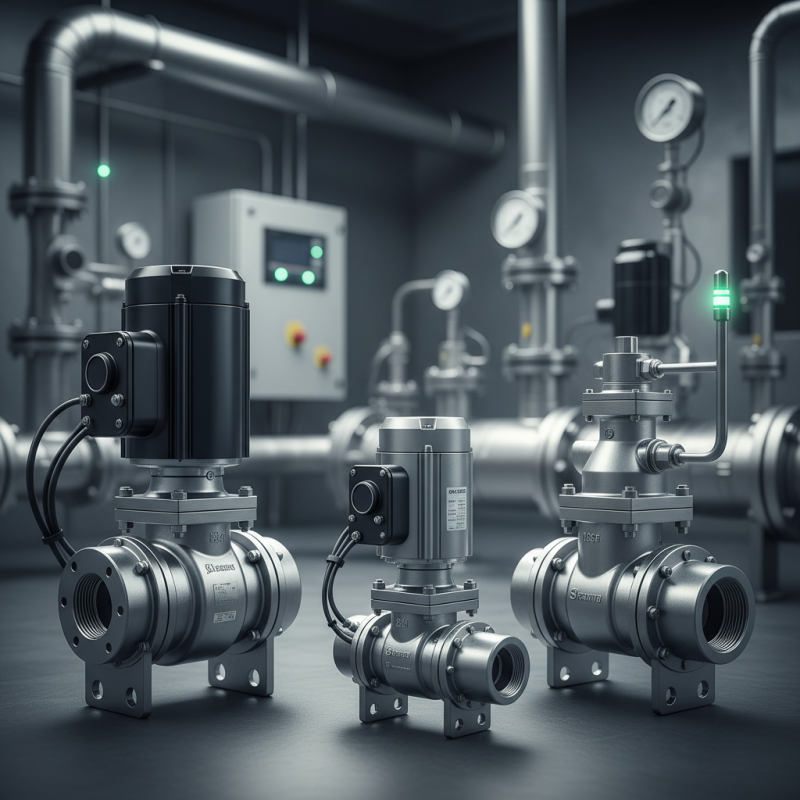

In the realm of industrial automation, choosing the right Motorized Valve is crucial. These valves play a vital role in controlling fluid flow efficiently. They minimize waste and enhance productivity in various systems. With options ranging from simple on/off valves to complex modulating types, the decision can feel overwhelming.

Several factors influence the choice of a Motorized Valve. The application, media type, and temperature are essential considerations. Each factor can greatly impact the performance and longevity of the valve. Some users find themselves facing challenges when selecting the most appropriate model. A wrong choice can lead to inefficiencies that could have been easily avoided.

By exploring the best Motorized Valve options for 2026, we aim to guide users through this complex landscape. Understanding the features that matter most will lead to better decisions. It’s essential to reflect on past experiences when choosing valves. With the right information, users can enhance control and efficiency in their operations.

Overview of Motorized Valves and Their Applications

Motorized valves play a critical role in various industries. They enable precise control over fluid flow in systems like HVAC, water treatment, and process control. According to a recent report by industry analysts, the global smart valve market is projected to grow at a compound annual growth rate (CAGR) of 10% from 2023 to 2030. This underscores the rising demand for efficient flow management solutions.

In applications such as irrigation and chemical processing, motorized valves enhance efficiency. They reduce manual labor and minimize errors. Advanced models offer features like remote control and automated feedback, increasing operational safety. However, installation and maintenance can be challenging. Incorrectly integrated systems may lead to costly downtime and suboptimal performance.

Moreover, selecting the right valve type is crucial. Different applications may require specific designs, such as globe valves or ball valves. A miscalculation in valve selection can result in ineffective flow control. According to industry insights, improper valve sizing accounts for nearly 15% of energy loss in systems. This highlights the importance of careful consideration in valve choice. There's always room for improvement in operational practices, reminding us to evaluate continually.

Key Features to Look for in Motorized Valves

When choosing a motorized valve, several key features can significantly influence efficiency. Look for valves with precise control capabilities. This ensures accurate adjustments to fluid flow. A responsive actuator is essential. It should react quickly to system demands. A smooth operation reduces wear and tear on the valve.

Another critical feature is durability. Valves made from strong materials, like brass or stainless steel, resist corrosion. This prolongs their lifespan. Consider the size and compatibility as well. A well-fitted valve enhances performance and reliability. However, even the best options may face challenges, like installation issues or maintenance needs.

Energy efficiency is also worth noting. Opt for valves designed to minimize energy consumption. This not only saves costs but also reduces environmental impact. Evaluate noise levels too. Some valves operate quietly, while others produce more sound. Striking a balance between noise and efficiency can be tricky. Keep these features in mind to make an informed decision.

Top Motorized Valve Brands for 2026

When considering motorized valves in 2026, several brands stand out for efficiency and reliability. These valves are crucial in managing fluid flows in various applications. Users often look for features that enhance performance and adaptability. A reliable motorized valve should have precise control mechanisms. They must withstand harsh conditions without faltering.

Many consumers express concerns about durability. Some valves may wear out faster than expected, leaving users unhappy. The choice of materials impacts longevity greatly. Investing in higher-quality materials can prevent frequent replacements. Innovative designs can also provide better seals, reducing leakage. A well-constructed valve reduces maintenance needs, saving time and resources.

User feedback is essential in evaluating brands. Some users report great performance, while others highlight issues. Not all valves work perfectly in every situation. It's important to assess the context in which the valve will be used. Market research can yield valuable insights. Reviews from real users often reveal aspects overlooked in technical specs. Understanding these nuances can guide better purchasing decisions.

2026 Best Motorized Valve Options for Efficient Control

| Valve Type | Size (inches) | Power Supply (V) | Operating Temperature (°C) | Flow Coefficient (Cv) | Features |

| Ball Valve | 1 | 24 | -20 to 100 | 20 | Quick Open, High Flow |

| Butterfly Valve | 2 | 230 | -10 to 90 | 25 | Compact Design, Lightweight |

| Gate Valve | 3 | 120 | 0 to 150 | 30 | Tight Seal, Low Friction |

| Globe Valve | 1.5 | 48 | -40 to 80 | 15 | Excellent Control, High Pressure |

Comparative Analysis of Efficiency in Motorized Valves

The comparative analysis of efficiency in motorized valves reveals crucial insights for industries reliant on precise flow control. According to a recent industry report, organizations can achieve up to 30% energy savings with the right motorized valve systems. Efficiency is not just about installation, but also about performance in varying conditions. A poorly matched valve can lead to significant losses.

Motorized valves must be selected based on their specific application. Parameters like pressure and flow rate affect efficiency. Data suggests that valves designed for high-capacity systems can sometimes lag in smaller applications, resulting in wastage. A wrong choice impacts not only costs but also operational effectiveness. Users must evaluate their needs carefully.

Another point of consideration is maintenance. Routine checks can enhance valve longevity and performance. Neglected components, however, can diminish efficiency over time. A surprising 25% of motorized valve issues stem from inadequate maintenance practices. Identifying the right balance between efficiency and upkeep is essential for sustained performance.

Future Trends in Motorized Valve Technology and Control Systems

Motorized valves are evolving rapidly. Future trends focus on smarter and more efficient control systems. These advances make operations seamless in various sectors. Enhanced connectivity and automation are key drivers of innovation. IoT integration allows real-time monitoring and analytics. This results in better performance and reduced downtime.

Tips: Monitor valve performance regularly. This can help catch issues early. Use predictive maintenance strategies. This approach minimizes unexpected problems.

Another trend is the application of AI and machine learning. These technologies can optimize control based on usage patterns. However, some users may struggle with complex systems. It can be daunting to integrate new technologies. A strong understanding is crucial for smooth operation.

Tips: Invest in training. Well-informed staff can make transitions smoother. Keep communication open with all team members. Their insights are vital for improvement.

2026 Best Motorized Valve Options for Efficient Control

This chart illustrates the projected efficiency improvements and adoption rates for various motorized valve technologies in the year 2026. Data reflects expected performance metrics based on current trends in automation and smart technology integration.