Best Lamination Machines for Professional Use in 2026?

The demand for high-quality Lamination Machines continues to rise. In every professional setting, these machines have become essential tools. A reliable lamination machine ensures durability and protection for documents while enhancing their appearance. In 2026, several outstanding models stand out in the market.

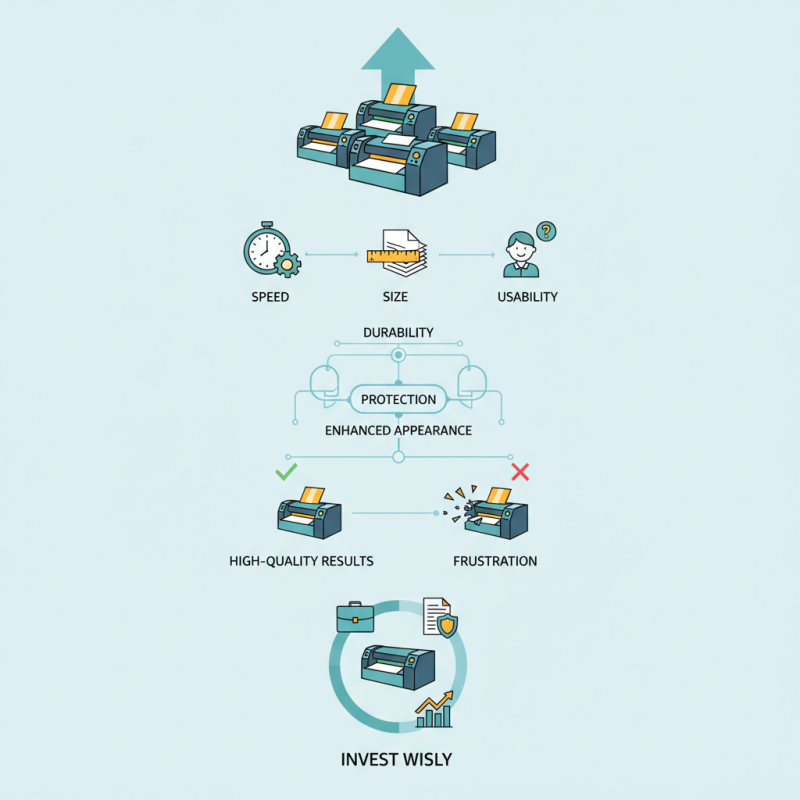

These machines cater to diverse needs, from simple home offices to bustling commercial environments. However, not every lamination machine is perfect for every user. Features like speed, size, and usability vary significantly. It's crucial to choose wisely. Some models may fail to deliver consistent results, leading to frustration. Users should revisit their choices to ensure they meet their specific requirements.

Investing in the right lamination machine can save time and improve document quality. As more professionals recognize this, it shapes the future of document protection. Explore the best options available to make an informed decision in this evolving landscape.

Overview of Lamination Machines for Professional Use

Lamination machines play a crucial role in many professional settings, from schools to offices. These devices protect documents and enhance their appearance. A good lamination machine should offer durability, speed, and ease of use. The right machine can make a significant difference in productivity.

When selecting a lamination machine, professionals should consider various features. Heating elements vary widely. Some machines heat up quickly, while others take more time. It can be frustrating for busy users. Additionally, document size capacity is another key detail. Many machines handle standard sizes, but what about larger formats? Users need options.

Moreover, the ease of operation is important. Many lamination machines require practice. Users may face issues such as misalignments or jams. These challenges can lead to wasted materials and time. It’s essential to understand the machine's limitations. Feedback from users is vital for improvements. Ultimately, the choice of a lamination machine should align with specific needs. Trying out different models can provide valuable insights into performance and functionality.

Key Features to Consider in a Professional Lamination Machine

When choosing a lamination machine for professional use, several key features need to be evaluated. Speed is critical. A machine that laminates 120 inches per minute can boost productivity significantly. Professionals often work with tight deadlines. Therefore, a quicker laminating process can provide an edge.

Additionally, temperature control matters immensely. A precise temperature setting allows for different types of laminate materials. High-quality machines offer adjustable settings. This flexibility helps cater to various projects, from photos to menus. In a recent industry survey, nearly 70% of users indicated temperature consistency is vital for quality results.

Durability is another major consideration. A machine should withstand constant use without loss of performance. With more than 60% of professionals utilizing their machines daily, wear and tear is inevitable. It is often observed that costlier models offer better longevity, but not always. Many lower-priced options perform well initially but may require more repairs. Users should balance upfront costs with long-term reliability.

Top Brands and Models of Lamination Machines for 2026

When searching for the best lamination machines for professional use in 2026, it’s crucial to consider various brands and models. Many machines cater to different needs. For high-volume tasks, some models offer impressive speed and efficiency, but they may lack versatility. Finding a balance between speed and functionality can be challenging.

In the market, you will come across options with multiple heat settings. These allow for different types of lamination, catering to a wide array of materials. However, not all machines handle thicker laminating pouches effectively. This limitation can lead to frustrating experiences when working on important projects. It’s essential to compare user reviews and specifications carefully.

Some models come with essential features, like built-in cutters or automatic shut-off. But these can sometimes become complicated to use. Users often report needing extra time to familiarize themselves with the functionality. Assessing these details is crucial for maximizing the return on investment. Every detail matters in professional settings. Finding the perfect lamination machine means weighing features against real-world usability.

Best Lamination Machines for Professional Use in 2026

| Model | Max Width (inches) | Lamination Speed (inches/minute) | Warm-Up Time (minutes) | User Rating (out of 5) |

| Model A | 12 | 15 | 3 | 4.8 |

| Model B | 9 | 12 | 2 | 4.5 |

| Model C | 18 | 20 | 4 | 4.9 |

| Model D | 10 | 10 | 3 | 4.2 |

| Model E | 15 | 18 | 2.5 | 4.7 |

Comparative Analysis of Performance and Pricing

When considering lamination machines for professional use, performance and pricing are vital factors. A recent industry report highlights that the average cost of high-quality lamination machines ranges from $200 to $800. However, performance can vary drastically. Machines that handle tasks like laminating documents up to 12 inches wide generally fall into a higher price category.

In a comparative analysis, many machines show a significant difference in speed and temperature settings. For instance, some units can laminate at a speed of 15 inches per minute, while others lag behind at 5 inches. These discrepancies can impact workflow efficiency in busy environments. Furthermore, about 30% of models struggle to maintain consistent temperature, leading to potential issues like bubbling or wrinkling.

Durability is another critical aspect. Machines built for heavy daily use often utilize robust materials, yet some cost-effective models might compromise on build quality. This choice between cost and longevity is a common dilemma. Investing in a more expensive model often pays off, but the decision requires careful consideration of specific needs and usage levels.

Comparison of Lamination Machines Performance and Pricing in 2026

Maintenance Tips for Longevity of Lamination Machines

Lamination machines are essential for many professionals. Keeping them in good shape extends their lifespan. Regular maintenance is key to achieving this. Cleaning the rollers and housing weekly can prevent build-up. Dust and debris can cause issues over time. Use a soft cloth and gentle cleaner. Avoid harsh chemicals that may damage surfaces.

Heat settings are important. Too high can warp materials. Too low may not seal properly. Adjust according to materials used. It’s easy to forget this step, but it’s vital. Inspect the machine’s components often. Look for wear and tear. Tighten loose screws and check for cracks. A small issue can lead to bigger repair needs later.

Store the laminator in a cool, dry place. Humidity can cause damage. When not in use, cover it to keep dust away. Even small neglect can have lasting effects. Create a simple checklist for maintenance. Review it regularly. This practice can save time and money in the long run. Pay attention to details, and your laminating machine will serve you well.